Made by HIRSCH

Hirsch

SOURCE OF BRACELET ART

Our HIRSCH headquarter in Klagenfurt (Austria) has always been regarded as the "source of bracelet art": this is the central point where all the "threads come together". All developments relating to the bracelet - from the idea to the finished product - take place here.

PRODUCTION PROCESSES

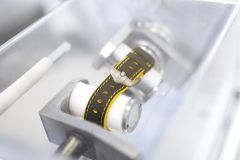

The production of a HIRSCH bracelet is highly sophisticated, and much of it is still done manually. A HIRSCH bracelet consists of three components:

- the upper leather (the side that faces you)

- the padding (inside the bracelet) and

- the lining (which is in direct contact with the skin)

To combine these three parts seamlessly and permanently, we use the so-called Rembordé technique, which was invented by the founder of the company, Hans Hirsch, and subsequently patented in 1955. This invention set a standard in the watch strap industry that continues to be recognised today.

This production method has a range of benefits:

- enclosed edges

- an invisible transition between the upper leather and the lining and the

- optimum protection against the intrusion of numerous substances, such as water, sweat, perfume, sun cream and solvents, to which the bracelet is exposed on a daily basis.

QUALITY AND INNOVATION

A bracelet is a product which is continually in direct skin contact and is worn for long periods of time. It is important that you can rely on its quality and are confident it will keep your watch safely on your wrist.

The durability of a bracelet is significantly influenced by its use and by its user’s day-to-day habits. So the product needs to be highly resilient.

HIRSCH bracelets are therefore “sauna-tested”, to make sure they can withstand even extreme combinations of heat, moisture and sweat. The same goes for contact with water. HIRSCH bracelets are therefore generally water-resistant and dry more quickly than conventional watch straps – for example, when you wash your hands or have any other contact with water.

Member of the AQC

HIRSCH is a founding member of the AQC.

The AQC (Association pour l'Assurance Qualité des Fabricants de Bracelets Cuir) was created to provide additional security for a watch brand, as AQC members fulfil the highest requirements in terms of traceability and conformity of the materials used in the manufacture of leather watch straps.

The association is committed to sustainable development by covering the entire leather strap supply chain. An audit is carried out every two years, which authorises members to continue to be part of the AQC.

Free gift

Free gift Free shipping from CHF 55

Free shipping from CHF 55 Easy return

Easy return Fast delivery

Fast delivery FAQ

FAQ